注塑成型的尺(chǐ)寸不僅要滿足使用和安裝的要求,還要考慮模(mó)具製造(zào)、設備性能和原材料的流動。嚴格控製影響注塑件精度的因素,包(bāo)括模具(jù)製造精度、塑料成(chéng)分和工藝條件。下麵

濟南注塑加工人員為您講解更多要滿足的要求。

The size of injection molding should not only meet the requirements of use and installation, but also consider mold manufacturing, equipment performance and raw material flow. Strictly control the factors affecting the precision of injection parts, including mold manufacturing precision, plastic composition and process conditions. Next, Jinan injection molding personnel will explain more requirements to you.

注塑成型的表麵粗糙度是由模具表麵的粗(cū)糙度決定的,所(suǒ)以模具的表麵粗糙(cāo)度比製品的表麵粗(cū)糙(cāo)度低一級(jí),通過打磨(mó)拋光達到要求。模腔內注塑件(jiàn)的冷卻(què)收縮使(shǐ)注塑件的取出困難。因此,為了便於脫模,在平行於脫模方向(xiàng)的內外表麵上應考慮足夠的脫模斜度。

The surface roughness of injection molding is determined by the surface roughness of the mold, so the surface roughness of the mold is one level lower than the surface roughness of the product, which can be achieved by grinding and polishing. The cooling shrinkage of the injection molded parts in the mold cavity makes it difficult to take out the injection molded parts. Therefore, in order to facilitate demoulding, sufficient demoulding slope shall be considered on the inner and outer surfaces parallel to the demoulding direction.

注塑成型是注塑模具的(de)成型方法。注塑成型的優點是生產速度快、效率(lǜ)高、自動化操作、顏色多(duō)樣、尺寸由(yóu)大變小(xiǎo)、產品尺寸容易改變、形狀複雜。在複雜形狀的大批(pī)量生產中,經常使用零件和注塑成型。

Injection molding is the molding method of injection mold. The advantages of injection molding are fast production speed, high efficiency, automatic operation, diverse colors, size changing from large to small, easy to change product size and complex shape. In the mass production of complex shapes, parts and injection molding are often used.

注塑成型是一個技術(shù)和實踐(jiàn)能(néng)力很強的行業(yè)。在注塑(sù)成型過程中使用(yòng)塑(sù)料原(yuán)料、碳粉、噴嘴、模具、注塑機、周邊設備、夾具、噴霧器、各種輔助材料和包裝材料。這些都給注塑車間的管理帶來了巨大的成就。與其他行業或部門相比(bǐ),注塑車間的各(gè)級管理人員都存在一定(dìng)的困難和更高的要求。

Injection molding is an industry with strong technical and practical ability. In the injection molding process, plastic raw materials, carbon powder, nozzles, molds, injection molding machines, peripheral equipment, fixtures, spray, various auxiliary materials and packaging materials are used. All these have brought great achievements to the management of injection molding workshop. Compared with other industries or departments, managers at all levels in the injection molding workshop have certain difficulties and higher requirements.

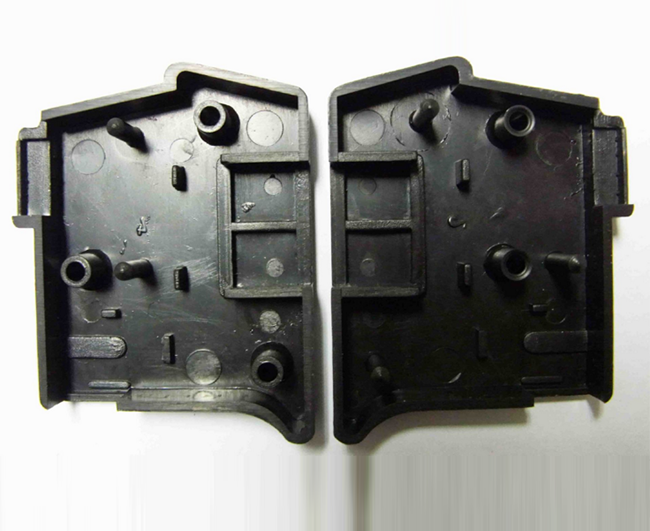

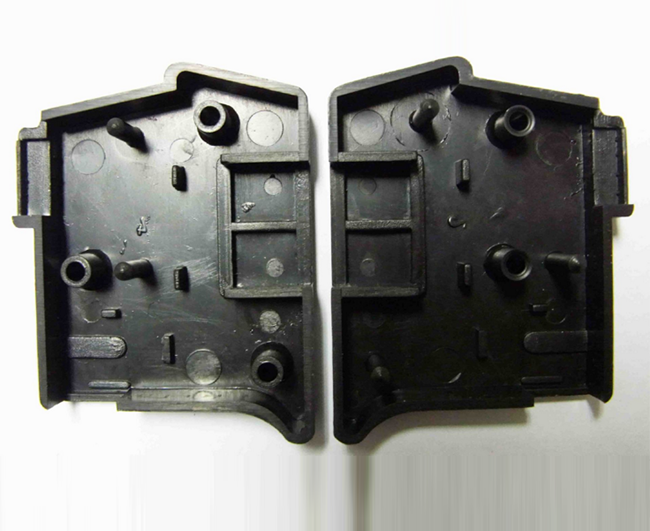

雖然模具的結構可能會因塑料(liào)的種類和性能、塑料製品的形狀和結構以及注塑機的類型而(ér)有(yǒu)所不同,但基本結(jié)構是相同的。模具主要由澆注係統、溫控(kòng)係統、成型件和結構件(jiàn)組成。澆注係統和模具與塑料(liào)直(zhí)接接觸,並且因塑料而異。它們是模具中比較(jiào)複雜和多變的零件,需要高精度的零件。

Although the structure of the mold may be different depending on the type and performance of plastic, the shape and structure of plastic products, and the type of injection molding machine, the basic structure is the same. The mold is mainly composed of pouring system, temperature control system, molding parts and structural parts. The gating system and mold are in direct contact with the plastic and vary from plastic to plastic. They are relatively complex and changeable parts in the mold, requiring high-precision parts.

此外注塑車間的(de)工種和分工繁多,不同的崗位對技能的要求也不同。為了使注塑車間的生產經營順利進行,需要對各個環節所涉(shè)及的人員、材料、設備和工具進行管理。關注我(wǒ)們網(wǎng)站

http://www.lsjtcyjt.cn,了解更(gèng)多相關住注塑加工事項!

In addition, there are many types of work and division of labor in the injection molding workshop, and different posts have different requirements for skills. In order to make the production and operation of the injection molding workshop go smoothly, it is necessary to manage the personnel, materials, equipment and tools involved in each link. Follow our website http://www.lsjtcyjt.cn Yes, learn more about injection molding!