在國(guó)內有很多的設備(bèi)或者(zhě)是儀器,以及生(shēng)活用品等等,都需要用到模具製造這個領域,如果模具製造這個領域出現了問題(tí)的話,也是難以滿足(zú)大家需求的。那麽幾個(gè)問題都是常見的注塑加工時候所(suǒ)發生的,了解清楚了(le)才能更好(hǎo)使用它。

In China, there are many equipment or instruments, as well as daily necessities, which need to be used in the field of mold manufacturing. If there are problems in the field of mold manufacturing, it is also difficult to meet everyone's needs. So several problems are common in injection molding processing. Only when we understand them clearly can we use them better.

製造的模(mó)具是(shì)否(fǒu)是特殊的結構和特殊的要求(qiú)?

Is the mold manufactured with special structure and special requirements?

比方模具要求是采用機械手來進行裝拆,如果在模具驗收過程中沒有考慮這一問題,必(bì)定影響安裝使用期(qī)限。這也說明不要隻把(bǎ)眼光盯在模具上是遠遠不夠的,一整套的模具係統都必須周全考慮。例如:型腔壓(yā)力傳感器、抽芯裝置、特殊的模(mó)具加(jiā)熱和冷卻方式(shì)、環(huán)境潔(jié)淨度、立式模具、多點注口模、機械手和取件裝置、配件處理方法等等。

For example, the mold is required to be assembled and disassembled by manipulator. If this problem is not considered in the mold acceptance process, the installation and service life will be affected. This also shows that it is not enough to only focus on the mold, and a complete set of mold system must be considered comprehensively. For example: cavity pressure sensor, core pulling device, special mold heating and cooling methods, environmental cleanliness, vertical mold, multi-point injection mold, manipulator and part taking device, accessory processing methods, etc.

原材料屬於通用的塑料還是工(gōng)程塑料?

Are the raw materials general plastics or engineering plastics?

一般而言的話。加工工程塑料的工藝比較複雜,特別(bié)是沒有經驗的注塑廠家。特別需注意的是那些加了加工玻璃纖維或者增強器尼龍材(cái)料的一些部件,可能需用到油加熱模具,以避免因為玻璃纖維導致製件表麵的遷(qiān)移,導致模具型腔或者型芯的損壞(huài)。接著應考慮對幹(gàn)燥設備、螺(luó)杆、機(jī)筒、止(zhǐ)逆環等(děng)機件需提高耐磨耗性和抗撕裂性能。

Generally speaking. The process of processing engineering plastics is relatively complex, especially for inexperienced injection molding manufacturers. Special attention should be paid to some parts with processed glass fiber or intensifier nylon materials, which may need to heat the mold with oil to avoid the migration of the surface of the workpiece caused by glass fiber, resulting in the damage of the mold cavity or core. Then it should be considered to improve the wear resistance and tear resistance of drying equipment, screws, barrels, check rings and other parts.

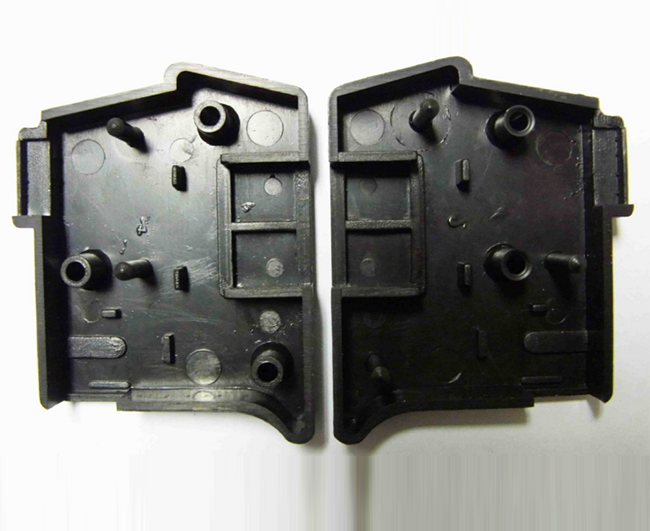

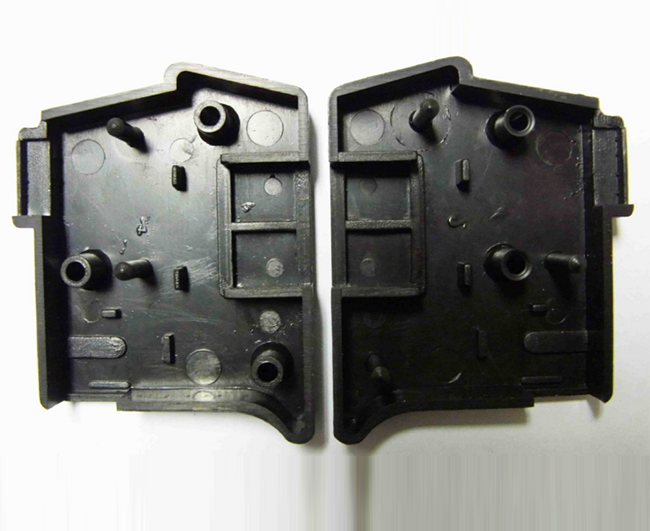

如何確定模具的(de)保養好壞(huài)與使用的年限呢?

How to determine the maintenance quality and service life of the mold?

時間的情況來說的話,模具的使用年限在模具的實(shí)際使用情況上來說不是很重要(yào)的因素,因為在(zài)模具(jù)使用中需關(guān)注的首先是模具的各種設計的模式、其製造的方法、各種維護保養狀況等因素。一套采用較低標準製造的新模(mó)具通常使用劣質鋼材來製造,同時也是沒有標(biāo)出分模線刻痕、頂(dǐng)出導軌(guǐ)位置,這樣設計的模具比較難用於注塑加工進行生產和保養。

In terms of time, the service life of the mold is not a very important factor in the actual use of the mold, because in the use of the mold, we should first pay attention to the various design modes of the mold, its manufacturing methods, various maintenance conditions and other factors. A set of new molds manufactured with lower standards are usually made of low-quality steel. At the same time, the scoring of the parting line and the position of the ejection guide rail are not marked. The molds designed in this way are difficult to be used for injection molding for production and maintenance.

定(dìng)做注塑模具需要時間?

How long does it take to customize the injection mold?

濟南注塑(sù)加工廠家(jiā)提(tí)醒(xǐng),凡是需要注塑模(mó)具定做之前,都要做好產品(pǐn)方案構思,按照方案構思做出產品(pǐn)的外觀設計和產品的功能結構,並繪製出產品的3d結構圖檔,建(jiàn)議是按該3d圖檔用(yòng)3d打印一套樣板,通過反複驗證結(jié)構和外觀(guān)沒有問題之後才可以進一步決(jué)定注塑模具定做。

Jinan injection molding manufacturers remind that before the injection mold is customized, we should do a good job in product scheme conception, make the appearance design and functional structure of the product according to the scheme conception, and draw the 3D structure drawing file of the product. It is recommended to print a set of samples in 3D according to the 3D drawing file. After repeatedly verifying that the structure and appearance are OK, we can further decide to customize the injection mold.

一(yī)般完成一套定製注塑(sù)模具(jù)需要45天至60天之間,這樣就化掉了(le)兩個月的時間了,再化一個月的時間去實施產品的裝配和功能調試(shì)。這樣就比較完美做個產品(pǐn)去市場參展了。

Generally, it takes 45 to 60 days to complete a set of customized injection molds, which takes two months and another month to implement product assembly and function debugging. In this way, it is more perfect to make a product and go to the market for exhibition.

以上就是問題解答的相關內容了,希望能夠幫(bāng)助到大家(jiā),如(rú)對這一問題還存在任何疑問,都(dōu)歡迎關注我們網站

http://www.lsjtcyjt.cn並谘詢我們的工作人員,將竭誠為您(nín)服務。

The above is the relevant content of the question answer. I hope it can help you. If you still have any questions about this problem, you are welcome to follow our website http://www.lsjtcyjt.cn And consult our staff, will serve you wholeheartedly.