在注塑模具(jù)使用中,模具損壞到修模都是在所難免的,隻有(yǒu)想辦法縮短修模(mó)的時候,這樣才可以提升注塑模具廠家的(de)生(shēng)產效益。那麽

山東模具製(zhì)造廠家有哪些(xiē)減少修模的方法呢?

In the use of injection mold, mold damage to mold repair is inevitable. Only by finding ways to shorten the time of mold repair, can we improve the production efficiency of injection mold manufacturers. So what are the ways for Shandong mold manufacturers to reduce mold repair?

1、生產控製(zhì)。類似表中熱流道塞鐵(tiě)及(jí)PIN針卡壞模(mó)具的事要盡(jìn)量避免。

1. Production control. Similar to the hot runner plug iron and pin pin pin in the table, it is necessary to try to avoid damaging the mold.

2、模具保養。平時(shí)生產中的一級二級保養和模修部門的三級保養要紮實到位,什麽拉絲灰塵披鋒要避免,彈簧斷/頂針卡/鏟雞(jī)起刺(cì)等都要避免(miǎn)。

2. Mold maintenance. The level-1 and level-2 maintenance in normal production and the level-3 maintenance in the mold repair department should be solid and in place. Any wire drawing dust should be avoided, and spring breakage / thimble sticking / chicken shovel stabbing should be avoided.

3、作業流程規範化,人員培訓及(jí)績(jì)效考核。

3. Standardization of operation process, personnel training and performance appraisal.

4、加(jiā)強科學注塑知識培訓,盡量在生產中不傷害模具。低壓保護設置、合模速度、鎖模力、注(zhù)射速度、保壓壓力、模溫等參數不當等都會大的損壞模具(jù),這是萬萬要注意的。

4. Strengthen the training of scientific injection molding knowledge, and try not to hurt the mold in production. Improper parameters such as low pressure protection setting, mold closing speed, mold locking force, injection speed, pressure holding pressure, mold temperature, etc. will greatly damage the mold, which should be paid attention to.

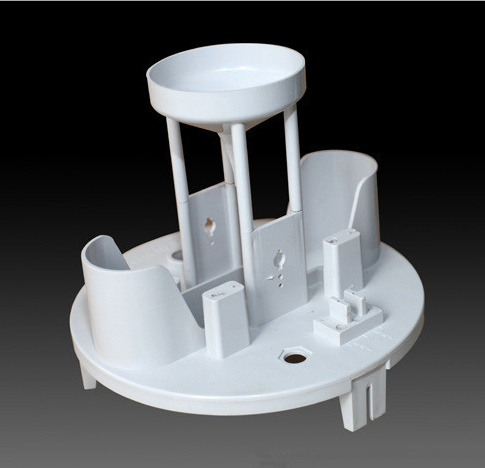

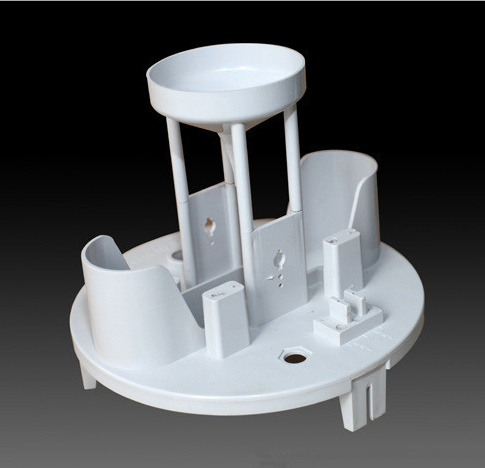

5、胎裏的毛(máo)病要避免。模具的設計和製造過程(chéng)就是“懷胎”,這時候的毛病不能(néng)有,否則維修是避免(miǎn)不了的。比如模具(jù)7大係統的設計、材質等。

5. Problems in the tire should be avoided. The design and manufacturing process of the mold is "pregnancy". At this time, there can be no problems, otherwise maintenance can not be avoided. For example, the design and material of the 7 major systems of the mold.

6、易損(sǔn)件的標準化及(jí)庫存。頂針/彈簧/司筒/導柱/導套等(děng)要盡量統一規格,備庫存。

6. Standardization and inventory of vulnerable parts. Thimble / spring / cylinder / guide post / guide sleeve, etc. should be unified in specification as far as possible and be kept in stock.

模具也要定期維護保養才行,模具注塑屬(shǔ)於比較昂貴的加工工藝,定期(qī)保養(yǎng)模具,有(yǒu)利於(yú)減少成本支出,選擇擁有完善保養維護係統流程的模(mó)具廠(chǎng)家,定期檢查(chá)各模具的磨損(sǔn)情況,詳細(xì)內(nèi)容就來我們網站

http://www.lsjtcyjt.cn谘詢吧。

Molds should also be maintained regularly. Mold injection molding is a relatively expensive processing process. Regular maintenance of molds is conducive to reducing costs. Select mold manufacturers with perfect maintenance system processes, and regularly check the wear of each mold. For details, please visit our website http://www.lsjtcyjt.cn Consult.