山東模具製造廠家在分型麵的選擇上的(de)選擇會影響開模後注塑件是留在動模腔內還是在(zài)定模腔內,進而影響注(zhù)塑件能否成型。那麽在選擇注塑模具分型麵時要注意什麽要點(diǎn)?

Shandong mold manufacturers in the selection of parting surface choice will affect the injection parts after opening the mold is left in the moving mold cavity or in the fixed mold cavity, and then affect the injection parts can be formed. So in the choice of injection mold parting surface should pay attention to what points?

脫模成功影響模具型腔的可加工性,分型麵是否會出現“飛邊”或分型麵的痕跡是否會(huì)影響注塑件的(de)尺寸(cùn)、形狀、壁厚、模具(jù)結(jié)構(gòu)、模具排氣和薄(báo)膜模具。因此,在選擇分型麵時,要綜合考慮(lǜ)各種影響因素、條件和要求,合理選擇分型麵。

The success of demoulding affects the machinability of the mold cavity, whether the parting surface will appear “flying edge” or the mark of the parting surface will affect the size, shape, wall thickness, mold structure, mold exhaust and film mold of the injection parts. Therefore, in the selection of parting surface, it is necessary to consider all kinds of influencing factors, conditions and requirements, reasonable selection of parting surface.

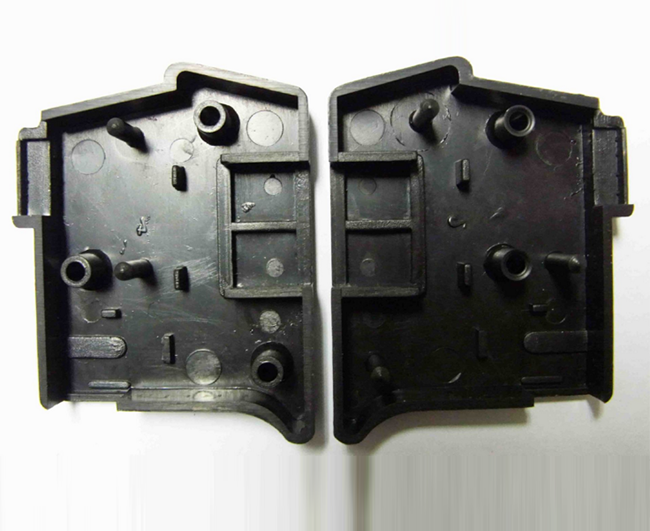

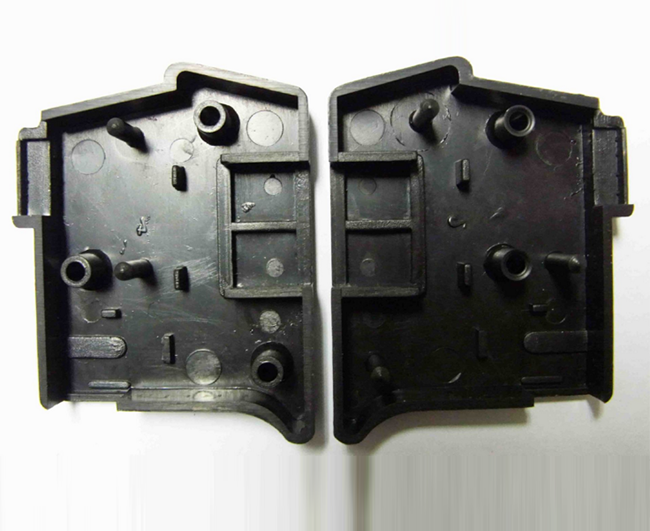

一般情況下,注塑件應(yīng)留(liú)在動模(mó)腔內(nèi),這樣(yàng)更便於注塑件(jiàn)的脫模(mó);應避免“障礙(ài)體”的阻礙,避免運動幹擾,以利於注(zhù)塑件(jiàn)的脫模和模腔的加工;應設置在不顯眼且易於去除飛邊、毛刺和易於加工的位置(zhì);應設置(zhì)在圓弧R的(de)切點以外(wài)的位置,無凹陷和圓弧(hú)。

In general, the injection parts should be left in the moving mold cavity, so that it is more convenient for the demoulding of injection parts; Should avoid the obstruction of “obstacle body”, avoid movement interference, in order to facilitate the demoulding of injection parts and mold cavity processing; Should be set in unobtrusive and easy to remove flaking, burr and easy to process position; It should be set outside the tangent point of arc R, without sag and arc.

應考慮澆口位置(zhì)及其形狀的設置;有利於澆注係(xì)統和排氣係統的布置;不影響注塑件的尺寸和精度;應考慮塑(sù)料的性能和填充條件;應考慮成型的加工性和效率;模具結構簡單,使用方便(biàn),可靠。

The locations and shape of the gate should be considered; Conducive to the layout of gating system and exhaust system; Does not affect the size and precision of injection parts; The properties and filling conditions of plastics should be considered; The processability and efficiency of molding should be considered; The mold structure is simple, easy to use, reliable.

由於分型麵受塑件在模具中的(de)成型位置、澆注係(xì)統的設計、塑件的結構可製造性和精度、鑲件的位置和(hé)形狀以及成型方法(fǎ)等(děng)多種因素的影(yǐng)響。頂出、模具的製造、排氣、操作工藝等因(yīn)素,因此在選擇分型麵時,應進行(háng)綜合分析比較,從幾種方案(àn)中選(xuǎn)擇更合理(lǐ)的(de)方案。

Because the parting surface is affected by the molding position of the plastic parts in the mold, the design of the pouring system, the manufacturability and precision of the structure of the plastic parts, the position and shape of the insert and the molding method and other factors. Ejecting, mold manufacturing, exhaust, operation process and other factors, so in the selection of parting surface, should be a comprehensive analysis and comparison, from several programs to choose a more reasonable program.

所以,這個問題的講解到此完畢了,如果您還有其他問題(tí)想要了解(jiě)的話(huà),歡(huān)迎來我(wǒ)們網站(zhàn)

www.lsjtcyjt.cn谘詢,客服(fú)會(huì)為您進行詳細的解答。

Therefore, the explanation of this problem is over, if you have other questions to understand, welcome to our website www.lsjtcyjt.cn consultation, customer service will be detailed answers for you.